Now that Cyril Ramaphosa has clinched the ANC’s top position, there’s hope that he may use his influence, mining union background and understanding of the sector to unlock regulatory change over the next few years to help improve the relationship between government and the industry. Ahead of the ANC’s national conference in December, Ramaphosa said it was vital for South Africa to begin to attain higher levels of mining exploration and investment to help the country create jobs and boost export revenues.

Shifts in the mining industry are inevitable if it wants to survive but a mammoth task lies ahead for mining companies.

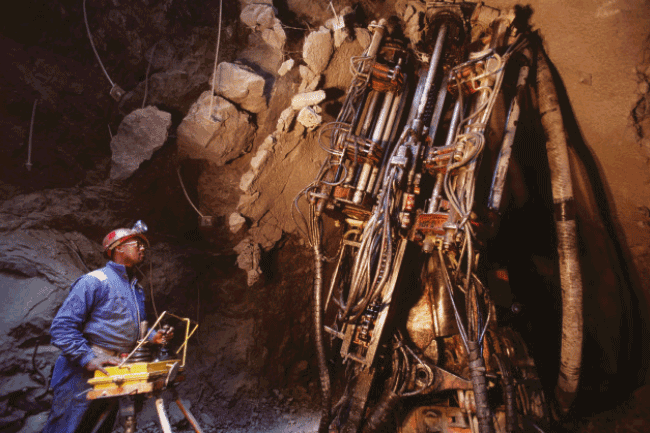

Much has been said about the challenges around the depth of South Africa’s gold and platinum mines, especially the former. It can take more than an hour for workers to reach the face of a mine, sucking up valuable time and posing higher health and safety risks. Hand-held rock drilling is also increasingly being seen as outdated and inefficient.

The Chamber of Mines has warned that sticking with the old could lead to premature mine closures and job losses. Research suggests 200 000 jobs may be slashed by 2025, affecting 2 million people who rely on the earnings of miners.

The Chamber has been resolute about emphasising that people are at the heart of the mining industry and that modernising the industry is not about replacing people with machines. A new mining order would need to focus on improving current skills and developing new ones. While there is fear that conventional mining jobs will be lost, this needs to be balanced with the view that other types of mining occupations will be created.

Firms are starting to plan and implement new ways of working. Anglo American is working on the ‘intelligent mine’, which uses big data, robotics and ‘machine learning’ to build a more connected mine. Anglo American CEO Mark Cutifani says Kumba Iron Ore’s Sishen mine is starting to make inroads. It is processing far less waste rock, and accessing precious metals and minerals more directly. The focus is sharply on innovation and resilience. Sibanye-Stillwater is testing small robots that can drill in tunnels less than 1.2m high and experimenting with ways to break rock without explosives. AngloGold Ashanti is using reef-boring technology and making inroads in shaft pillar mining.

Gold Fields has been investing in new technologies to make extracting ore more profitable, and established partnerships to implement technological advances such as rugged sensors, 3D vision and mapping software for use in mapping and inspection, geological monitoring and fleet tracking. And its South Deep mine uses remote-controlled equipment to break rock that has been transferred from the slopes to the ore pass system.

Technology is now available for open-pit autonomous trucking, remote-controlled support, remote-controlled train transport, autonomous excavators and a range of drone equipment. The industry is starting to embrace the concept of digital mining that will convert conventional mining practices.

Miners are also aware that engineers of the future will need to carve out a new way of mining in South Africa, and so education in new techniques and technologies is crucial. Partnerships between mining firms and tertiary institutions must be developed and funding provided. For example, Gold Fields has partnered with Wits University in a recent ZAR6 million, three-year deal that aims to further academic knowledge in the field of mechanised mining and rock engineering.

A move towards more mechanisation could propel the industry into a more productive, safer and cost-effective new era in mining. Now what is needed is for the industry to convince the government and unions that modernising the mines could lead to spin-off industries and create more jobs in the long run.